Table Of Contents

Explore the Benefits of Custom Aluminum Busbars for Efficient Electrical Solutions

Key Takeaways

- Summary of custom aluminum busbars and their characteristics

- Varieties of aluminum busbars available in the market

- Advantages of utilizing customized aluminum busbars

- Process involved in the fabrication of custom busbars

- Capability considerations for aluminum busbars

- Performance assessment between aluminum and copper busbars

- Uses and applications of aluminum busbars in various industries

Overview of Custom Aluminum Busbars

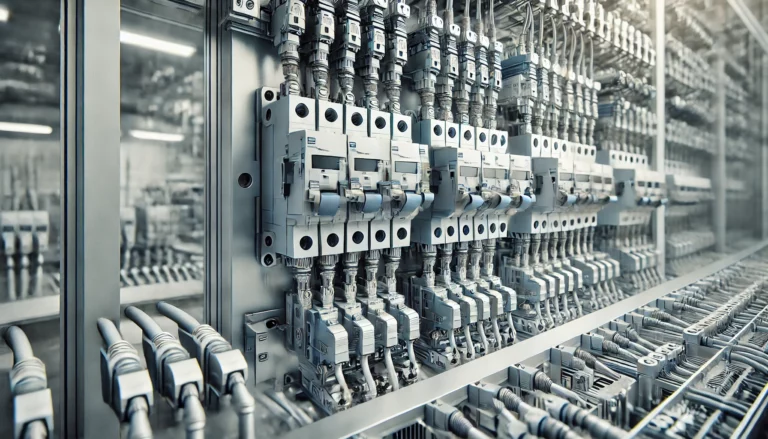

Custom aluminum busbars are essential components in electrical systems, providing an efficient means of distributing electrical power. They are made from aluminum, which is known for its excellent conductivity and lightweight properties. Customization in busbar design allows for tailored solutions that meet the specific requirements of various applications. The significance of these custom aluminum busbars cannot be overstated, as they enhance performance and reliability in power distribution networks. With an increasing demand for efficient energy solutions, the role of aluminum busbars is becoming more critical in both industrial and commercial settings.

Definition of Aluminum Busbars

Custom aluminum busbars are conductive components that facilitate the distribution of electrical power within various systems. Made from aluminum alloy, these busbars are designed to handle high currents while minimizing energy loss efficiently. Aluminum’s excellent conductivity and lightweight properties make it an ideal candidate for electrical applications. Customization of aluminum busbars allows for tailored solutions to meet specific electrical requirements in different environments.

Aluminum can be shaped into various configurations to accommodate a project’s unique needs. These custom aluminum busbars provide flexibility in design and installation, enhancing overall system performance. Their ability to resist corrosion further extends their use in diverse applications, ensuring reliability and longevity in power distribution. The combination of these features makes custom aluminum busbars an essential component in modern electrical infrastructure.

Importance of Busbar Products in Electrical Systems

Custom aluminum busbars serve a critical role in electrical systems by efficiently conducting electricity while minimizing energy losses. Their lightweight nature compared to steel makes them an ideal choice for various applications, including rail transportation. The oxidation of aluminum leads to the formation of aluminum oxide, which provides a protective layer, enhancing the longevity and performance of these busbars in demanding environments.

The versatility of custom aluminum busbars allows them to be tailored for specific applications within the electrical infrastructure. They can be designed to accommodate varying levels of current and voltage, making them suitable for both heavy industry and commercial use. The combination of durability and adaptability ensures that custom aluminum busbars meet the growing needs of modern electrical systems, making them indispensable in a range of settings.

Types of Aluminum Busbars

Aluminum busbars come in various types to meet specific electrical needs and applications. Standard aluminum busbars are commonly used in industrial settings, providing reliable conductivity and efficiency. Customized aluminum busbars are tailored to meet unique specifications, often utilized in transportation and vehicle manufacturing where lightweight and high-performance materials are essential. These custom designs may incorporate mild steel for enhanced structural integrity. Lightweight busbars are increasingly popular due to their ease of installation and adaptability, making them ideal for modern electrical systems that prioritize efficiency and functionality.

| Busbar Type | Material Composition | Typical Applications |

|---|---|---|

| Standard Aluminum Busbars | Pure Aluminum | Industrial settings, Power distribution |

| Customized Aluminum Busbars | Aluminum with Mild Steel | Vehicle manufacturing, Transportation |

| Lightweight Busbars | Aluminum Alloy | Modern electrical systems, Renewable energy |

| Busbar Trunking Systems | Aluminum and Insulation | Commercial buildings, Data centers |

Standard Aluminum Busbars

Custom aluminum busbars are a vital component in various electrical systems, particularly in automotive applications and panelboards. These busbars provide a reliable way to distribute electrical power efficiently. The lightweight nature of aluminum, combined with its excellent conductivity, makes it an ideal choice for manufacturers looking to optimize performance while maintaining structural integrity. Their versatility allows them to be used in a range of configurations and setups tailored to specific requirements.

Standard designs often do not account for unique project needs, leading many industries to opt for custom aluminum busbars. These tailored solutions can cater to specific load requirements and spatial constraints, ensuring that the electrical system functions optimally. The use of metal in busbar construction ensures durability and resistance to environmental factors, enhancing the overall lifespan of electrical installations.

Customized Aluminum Busbars

Custom aluminum busbars are designed to meet the unique specifications of various electrical systems. They can be tailored in terms of size, shape, and conductivity to suit specific applications. Companies often opt for custom aluminum busbars to enhance performance and ensure efficient power distribution. Manufacturing these custom solutions allows for increased flexibility in design, enabling engineers to effectively address both technical requirements and physical space constraints.

The adaptability of custom aluminum busbars makes them a popular choice in diverse industries. Whether for large-scale industrial applications or compact commercial settings, these customized solutions facilitate optimal functionality. By utilizing custom aluminum bus, businesses can achieve a balance between performance and sustainability. The result is an aluminum busbar product that not only meets precise requirements but also contributes to the overall efficiency of electrical systems.

Lightweight Busbars

Lightweight designs are revolutionizing the use of custom aluminum busbars in various applications. The reduced weight of aluminum custom bus solutions allows for easier handling and installation, leading to significant time savings during assembly. These aluminum bus bars offer the same level of electrical conductivity while minimizing the structural load on mounting systems and supporting equipment.

The lightweight nature of these components enhances their versatility across different settings. Industries focusing on renewable energy and electric transportation solutions benefit greatly from incorporating aluminum bus bars. Custom aluminum busbars can be designed to meet specific requirements without compromising on performance or reliability, making them an ideal choice for modern electrical systems.

Benefits of Using Custom Aluminum Busbars

Custom aluminum busbars offer significant advantages in electrical systems due to their enhanced aluminum busbar conductivity and lightweight characteristics. These lightweight busbar solutions not only facilitate easier installation but also optimize the overall performance of electrical networks. The durability and longevity of custom aluminum busbars make them a preferred choice for various applications, ensuring that they withstand demanding conditions over time. Cost-effectiveness is another key benefit, allowing businesses to reduce operational expenses while maintaining high-quality performance. By incorporating custom aluminum busbars, industries can achieve a balance of efficiency and reliability that is crucial for modern electrical infrastructures.

Enhanced Electrical Conductivity

Custom aluminum busbars demonstrate superior electrical conductivity compared to other materials, making them ideal for various applications. The inherent properties of aluminum allow these solid busbars to efficiently transmit electrical currents. This attribute is particularly beneficial in environments where reliability and performance are crucial, such as in power distribution and industrial systems. High-quality, top aluminum bus options capitalize on this conductivity, ensuring minimal energy loss in large busbars.

The design of custom aluminum busbars incorporates advanced engineering techniques that optimize their electrical pathways. This careful consideration results in enhanced performance and lower resistance, which contributes to their efficiency. By utilizing solid busbar configurations, manufacturers can achieve better heat dissipation and overall system reliability. Consequently, these custom solutions become integral to systems that demand high-performance electrical components.

Durability and Longevity

Custom aluminum busbars are renowned for their exceptional durability, making them a preferred choice in various electrical systems. The robust nature of aluminum allows these busbars to withstand harsh environmental conditions, including extreme temperatures and humidity. This resilience is crucial for applications where reliability is paramount. The busbar production department focuses on creating customized busbar solutions that prioritize strength and longevity, ensuring that these components perform effectively over time.

Longevity is another significant advantage of custom bus bars, as they require minimal maintenance throughout their lifecycle. Their resistance to corrosion contributes to their extended service life, reducing replacement frequency and associated costs. By investing in high-quality custom aluminum busbars, businesses can enjoy peace of mind knowing that their electrical infrastructure is equipped with components designed for optimal performance and durability. This reliability supports various applications, from industrial facilities to renewable energy systems.

CostEffectiveness

Custom aluminum busbars offer significant cost savings for various electrical applications. Their lightweight nature reduces transportation and installation costs compared to heavier alternatives like copper. This lower weight allows for easier handling and less labor time during the assembly of rigid busbars. For your next busbar project, considering the financial benefits associated with custom aluminum busbars can greatly enhance project efficiency.

The versatility of custom aluminum busbars also contributes to their cost-effectiveness. Whether opting for a rigid busbar or a flexible busbar, tailored solutions can meet specific operational needs without overspending on unnecessary features. This customization leads to efficient design and resource utilization, making it easier to stay within budget while maximizing performance for various applications.

Custom Busbar Fabrication Process

The fabrication of custom aluminum busbars involves several crucial design considerations to ensure they meet specific electrical requirements and physical constraints. Factors such as the desired busbar size and thickness play a significant role in the overall performance and efficiency of the custom bus bar. Engineers must assess the application to determine if a thick buss bar is necessary for high-capacity demands. Tailoring the dimensions and characteristics of custom aluminum busbars enhances their suitability for a variety of environments, from industrial settings to renewable energy systems. This precise approach ensures that the final product not only fulfills operational needs but also maintains durability and functionality over time.

Design Considerations for Aluminum Busbars

Designing custom aluminum busbars requires careful consideration of several factors to ensure optimal performance in electrical systems. The dimensions of the aluminum bar play a crucial role in its current-carrying capacity. Adequate spacing and configuration of bus bar joints are essential for reducing electrical resistance and minimizing heat generation. The use of high-quality materials in custom aluminum busbars contributes to their overall efficiency and effectiveness.

Choosing the appropriate finish for custom aluminum is also important. Surface treatments can prevent corrosion and enhance the lifespan of aluminum busbars, making them suitable for various environments. The design must take into account factors such as thermal expansion and mechanical stress to ensure reliability. Customization allows for adjustments in shape and size to meet specific application requirements, leading to a more efficient electrical distribution system.

- Proper thickness is essential for handling expected load currents without overheating.

- Ensure adequate ventilation around busbars to facilitate heat dissipation.

- Incorporate insulation materials where necessary to prevent electrical shorts.

- Analyze the potential for vibration and choose mounting options that minimize movement.

- Evaluate the environmental conditions and select finishes that withstand specific corrosive elements.

- Implement redundancy in design for critical applications to enhance reliability.

- Consider future scalability or modifications when designing the busbar system.

Manufacturing Techniques for Customized Aluminum Busbars

Various techniques are employed to fabricate custom aluminum busbars, ensuring they meet specific requirements for performance and application. Common methods include extrusion, stamping, and machining, each designed to manipulate bus bar material into precise shapes and sizes. These techniques allow manufacturers to create a range of configurations that enhance the functionality of the busbars while reducing production costs. By utilizing advanced technology and skilled craftsmanship, companies can offer value-added busbar services tailored to individual needs.

Quality and precision are paramount in the fabrication process of custom aluminum busbars. Implementing computer-aided design (CAD) software enables engineers to conceptualize and simulate the busbar design before production. This process minimizes errors and optimizes the layout for electrical efficiency. Maintaining strict quality control throughout production ensures that the final products meet industry standards and customer specifications. Custom aluminum busbars manufactured with these techniques are vital for effective power management in various applications.

Quality Control Measures

Implementing rigorous quality control measures is crucial in the fabrication of custom aluminum busbars. Each stage of production, from material selection to final inspection, plays a significant role in ensuring the effectiveness of the finished product. Utilizing advanced techniques, manufacturers assess the integrity of aluminum alloys to produce bus bars that meet or exceed industry standards. Special attention is paid to the dimensions and characteristics of thicker bus bars, which are often designed for high-capacity applications.

Testing and validation are essential components in the quality assurance process of custom aluminum busbars. Regular inspections help identify any potential issues before the bus bars are deployed in electrical systems. Visual inspections, electrical conductivity tests, and stress analyses ensure that each rhi busbar can perform optimally under varying conditions. Effective quality control not only enhances product reliability but also reinforces customer trust in the performance of custom aluminum busbars in critical applications.

Capacity of Aluminum Busbars

Understanding the capacity of custom aluminum busbars is crucial for their effective application in electrical systems. Custom aluminum busbars are designed to handle specific electrical loads, which can vary significantly depending on the requirements of the installation. In many cases, aluminum offers a compelling alternative to copper bus bars due to its lightweight nature and cost efficiency. Factors such as ambient temperature, environmental conditions, and installation layout greatly influence the capacity of a bus bar. Evaluating these aspects helps ensure that the aluminum busbars meet the performance standards necessary for reliable operation in various applications.

Factors Influencing Busbar Capacity

The capacity of custom aluminum busbars can vary significantly based on several factors. One crucial aspect is the design and construction of the busbar itself. For instance, strategic bus bars designed for high-current applications will have a different capacity compared to standard electrical bus bars. The thickness, width, and overall geometry play pivotal roles in determining the amount of electrical current a busbar can safely carry.

Another important factor is thermal management. Effective cooling mechanisms must be in place to dissipate heat generated during operation. This is particularly vital for potential equalization busbars, which are often subjected to varying loads across different phases. Proper heat dissipation not only boosts performance but also extends the lifespan of custom aluminum busbars, making them a reliable choice for various electrical systems.

Applications Requiring HighCapacity Aluminum Busbars

High-capacity aluminum busbars are essential in various applications where significant electrical loads must be distributed efficiently. Industries such as manufacturing, data centers, and transportation systems often require custom aluminum busbars to meet their specific energy demands. By utilizing quality aluminum, these busbars effectively manage large currents while minimizing power loss. The use of aluminum connectors also enhances the reliability and performance of these systems, ensuring safe and efficient operation under high-stress conditions.

Custom aluminum busbars play a critical role in renewable energy applications, particularly in solar and wind energy installations. These setups require robust and efficient power distribution solutions to handle the fluctuating loads generated by renewable sources. Bus bar fabrication techniques tailored for high-capacity needs ensure that the aluminum busbars can withstand extreme operational conditions. The durability and lightweight nature of aluminum further contribute to its suitability in these applications, providing a reliable solution for modern energy systems.

| Application | Industry | Typical Load Capacity | Material Benefits |

|---|---|---|---|

| Data Centers | Information Technology | Up to 5000 A | Lightweight, corrosion-resistant |

| Manufacturing Facilities | Industrial | Up to 3000 A | Efficient current distribution |

| Solar Energy Systems | Renewable Energy | Up to 2000 A | Robust under fluctuating loads |

| Wind Energy Installations | Renewable Energy | Up to 2500 A | Durable and lightweight |

| Transportation Systems | Transport | Up to 4000 A | High electrical conductivity |

Performance Comparison: Aluminum vs. Copper Busbars

The comparison between aluminum and copper busbars highlights several critical differences affecting their use in electrical systems. Custom aluminum busbars are increasingly favored due to their lightweight nature and excellent conductivity. While copper materials traditionally offer higher electrical conductivity, advancements in aluminum materials have improved their performance, making them suitable for various applications. Aluminum air provides effective heat dissipation, contributing to the longevity of custom aluminum busbars in demanding environments. The choice between these two options often hinges on factors such as weight, installation ease, and overall cost, with aluminum busbars providing significant advantages in many industrial and commercial contexts.

Conductivity and Efficiency

Custom aluminum busbars are designed to optimize conductivity in various electrical applications. With the right specifications, these busbars can outperform traditional copper alternatives in specific contexts. Information busbar manufacturing emphasizes the importance of selecting the correct bus bar to meet the demands of a given project. Experts recommend consulting resources like aluminum.org for insights on improving efficiency through appropriate aluminum busbar designs.

The efficiency of custom aluminum busbars is influenced by their structural integrity and surface treatment. Proper fabrication techniques ensure minimal resistance, leading to better performance in power distribution systems. The lightweight nature of aluminum contributes to ease of installation while maintaining high conductivity levels. Understanding the specific requirements of each application plays a crucial role in maximizing the benefits of custom aluminum busbars.

Weight and Installation Considerations

The weight of custom aluminum busbars plays a significant role in the feasibility and efficiency of installation in various applications. High strength aluminum offers a robust solution while maintaining a lightweight profile. This characteristic simplifies the handling and positioning of bus bars during installation. Bus bar connectors also benefit from the reduced weight, making it easier for technicians to assemble and connect components without the risk of strain or damage to the infrastructure.

Installation considerations of custom aluminum busbars extend beyond mere weight. The lightweight nature of these busbars allows for greater flexibility in design and layout, accommodating various spatial constraints. The use of custom aluminum busbars can minimize the need for extensive supports, reducing overall installation costs. Efficient installation processes contribute to quicker project completions, enhancing productivity while ensuring optimal performance in electrical systems.

- The lightweight design facilitates easier transportation and handling on-site.

- Custom sizing options ensure compatibility with existing infrastructure.

- Reduced installation time translates to lower labor costs.

- Aluminum’s corrosion resistance enhances longevity and reduces maintenance needs.

- Simplified installation process minimizes the risk of installation errors.

- Flexibility in layout design can lead to innovative electrical solutions.

- Improved safety for technicians due to decreased physical strain during installation.

Cost Implications

The financial considerations surrounding custom aluminum busbars are pivotal for many industries. Sourcing from American-based aluminum suppliers can ensure quality while reducing transportation costs. Using effective bus bar fasteners can also help optimize installation expenses, enhancing the overall cost-effectiveness of the project. Investing in aluminum rails provides added structural integrity, allowing for more straightforward integration of custom aluminum busbars into existing systems.

Long-term savings are realized through the durability and low maintenance requirements of custom aluminum busbars. Although initial setup costs may fluctuate, the longevity of these components often offsets upfront expenses. High-quality materials and proper installation techniques can significantly influence the overall financial impact, making it crucial to partner with reliable manufacturers and suppliers to maximize efficiency and minimize unexpected costs.

Applications of Aluminum Bus Bars

Custom aluminum busbars play a vital role in various applications, particularly in industrial and commercial environments where efficient power distribution is essential. These bus systems leverage aluminum’s excellent conductivity to minimize energy loss, making them preferable for many operations. While aluminum conducts electricity well, it is also important to consider its susceptibility to corrosion, which can impact its longevity and performance. Custom aluminum busbars can be designed to mitigate such issues, ensuring reliability in demanding settings. Industries increasingly turn to these tailored solutions to meet specific power requirements while maintaining cost-efficiency and operational effectiveness.

Industrial and Commercial Use Cases

Custom aluminum busbars find extensive applications in both industrial and commercial environments due to their excellent electrical properties. The use of pure aluminum provides significant advantages, such as reduced weight compared to traditional copper alternatives. This lightweight characteristic facilitates easier installation, especially in complex setups where space is limited. The closed aluminum oxide layer naturally formed on the surface of pure aluminum also enhances its corrosion resistance, ensuring longevity and reliability in various conditions.

In manufacturing and power distribution settings, custom aluminum busbars are essential for efficient electrical distribution. Their ability to handle high current loads while maintaining low resistance makes them ideal for both industrial machinery and commercial infrastructure. Industries such as renewable energy, where efficient energy transfer is crucial, greatly benefit from the use of these custom solutions. The metall properties of custom aluminum busbars contribute to overall system performance and reliability, making them a preferred choice for numerous applications.

Use in Renewable Energy Systems

Custom aluminum busbars play a crucial role in renewable energy systems, particularly in solar and wind energy installations. These bars are designed to handle high current loads while maintaining efficiency. Their lightweight nature makes them ideal for outdoor applications, where they are often mounted on rails or structures, providing a reliable and effective means of power distribution.

The use of custom aluminum busbars ensures optimal performance in harsh environmental conditions. Their corrosion resistance enhances their suitability for outdoor applications, contributing to the longevity of renewable energy systems. By utilizing these specialized bars, companies can improve the overall efficiency and reliability of their energy solutions, supporting the growing demand for sustainable power sources.

Role in Power Distribution Networks

Custom aluminum busbars play a crucial role in power distribution networks by efficiently channeling electrical energy to various equipment and vehicles. The bar design of these busbars allows for high current carrying capacities, making them suitable for applications requiring a reliable power supply. This capability enhances the overall performance of electrical systems, ensuring that power is distributed evenly and effectively.

The versatility of custom aluminum busbars enables their integration into numerous configurations within power distribution systems. Their lightweight nature and robust construction make them ideal for use in both stationary and mobile equipment. Industries increasingly rely on custom aluminum busbars to optimize their electrical infrastructure, leading to improved efficiency in energy utilization and performance across various applications.

Conclusion

Custom aluminum busbars offer a unique solution for electrical systems, characterized by their exceptional pure aluminum conductivity and customizable thickness to meet specific requirements. These busbars play a critical role in enhancing performance while remaining lightweight, making them ideal for a variety of applications. By opting for custom aluminum busbars, engineers and designers can ensure optimal efficiency and durability, addressing the diverse needs of modern power distribution networks. The combination of adaptability and superior material properties makes them a preferred choice for industries looking to maximize effectiveness in their electrical infrastructure.

FAQS

What are the advantages of using custom aluminum busbars compared to traditional materials in electrical applications?

Custom aluminum busbars provide several benefits, including being lightweight busbar-solutions aluminum, which makes them easier to install and manage. In addition, manufacturers can fabricate bus bars to specific design requirements, ensuring optimal performance. It’s also important to note that while aluminum corrodes more readily than some other materials, the right coatings can enhance its durability in various environments. For more detailed information on busbar manufacturing, interested parties can consult with industry experts.

How can I find reliable suppliers for custom aluminum busbars and aluminum buss bars?

To find reliable suppliers for custom aluminum busbars and aluminum buss bars, you can start by researching online directories that specialize in busbar manufacturing. Additionally, attending industry trade shows and reaching out to professionals in the field can provide valuable information on reputable suppliers for your needs.

What information should I consider when choosing custom aluminum busbars for my project?

When selecting custom aluminum busbars, it’s important to gather comprehensive information about busbar manufacturing processes, specifications, and performance metrics to ensure they meet your project’s electrical requirements.

What are some important factors I should consider about aluminium busbars and custom aluminum buss when selecting them for my electrical systems?

When selecting aluminium busbars and custom aluminum buss for your electrical systems, it’s essential to consider several key factors. You should evaluate the electrical conductivity, thermal performance, and mechanical properties of the materials. Additionally, look for specific information on busbar manufacturing processes, such as how they are fabricated and the quality standards they meet, as these can significantly influence the efficiency and reliability of your electrical systems.

What information should I know about busbar manufacturing when selecting custom aluminum busbars for my project?

When selecting custom aluminum busbars, it is important to gather information on busbar manufacturing processes, including material specifications, design considerations, and compliance with industry standards. This information will ensure that the custom aluminum busbars meet your project requirements and operate efficiently within your electrical systems.

What information should I have about busbar manufacturing processes when considering custom aluminum busbars for my electrical applications?

When considering custom aluminum busbars for your electrical applications, it’s essential to have information about busbar manufacturing processes, as this will help you understand the quality, durability, and performance of the product. Factors like the methods used in fabrication, the materials quality, and the applicable standards can significantly impact the efficiency and reliability of your custom aluminum busbars.

What key information should I understand about busbar manufacturing processes when sourcing custom aluminum busbars for different electrical applications?

When sourcing custom aluminum busbars for different electrical applications, it’s important to have detailed information about the busbar manufacturing processes. Understanding how these processes affect the performance, durability, and overall quality of custom aluminum busbars will help ensure that they meet your project’s specifications and requirements.

What key details should I keep in mind regarding information busbar manufacturing while sourcing custom aluminum busbars?

When sourcing custom aluminum busbars, it’s essential to understand various aspects of information busbar manufacturing, including the materials used, production techniques, and quality control measures. This knowledge can help ensure that the busbars meet your specific electrical requirements and are fabricated to the highest standards.

What types of information should I gather about different busbar manufacturing techniques when evaluating custom aluminum busbars for my application?

When evaluating custom aluminum busbars for your application, it’s essential to gather comprehensive information about various busbar manufacturing techniques. Understanding the information busbar manufacturing processes can help you assess the quality, durability, and suitability of the busbars for your specific electrical requirements. Factors such as material selection, production methods, and quality control measures are crucial to ensure you choose the best custom aluminum busbars for your needs.

What specific information should I consider about busbar manufacturing when selecting custom aluminum busbars for my electrical system?

When selecting custom aluminum busbars, it’s essential to gather information related to busbar manufacturing, including production methods, materials used, quality assurance processes, and any customization options available. This information will ensure that the custom aluminum busbars meet the specific requirements of your electrical applications, optimizing performance and reliability.